VDC/BIM DEPARTMENT

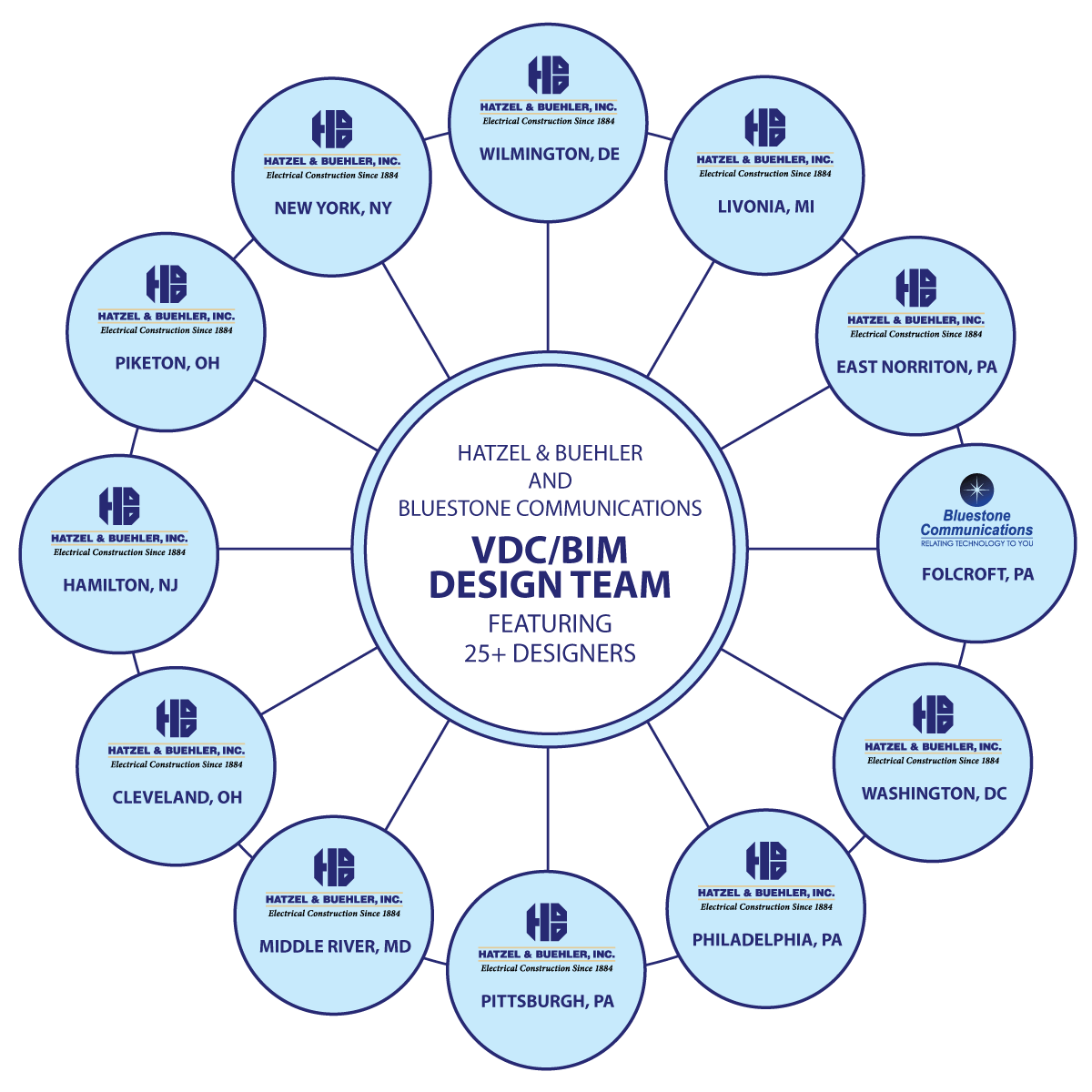

Hatzel & Buehler employs a full staff of qualified VDC/BIM Operators. This team works hand in hand with Hatzel & Buehler’s project management to offer the most efficient installation possible.

Our modeling team leader reviews all the contract documents, specifications & drawings to validate a work direction. At this time we will distribute the specific systems/work load to its members. Once systems have been assigned, the team member would meet with the entire coordination team to establish lines of communication and file distribution. Hatzel & Buehler knows the importance of coordination and holds weekly coordination meetings for progress, conflict detection and solution directions. We will provide construction plans to engineers for approval and offer sign-offs on other trade designs to prevent conflicts.

After modeling has been completed and approved, we send out specific items to our pre-fabrication facility for production. Our modeling team takes their design and provides points that can be utilized for our laser layout tool in the field. They also provide a full set of design drawings that can be used throughout the lifecycle of the building.

DESIGN-ASSIST ENGINEERING TEAM EXPERIENCE

Hatzel & Buehler uses an experienced approach to our client’s design assist projects with our in-house VDC/BIM design team capabilities and expertise to a construction project. Hatzel and Buehler has extensive experience working as a trade partner on a design-assist project, we provide an early review of the specifications and design narrative with appropriate questions and scope clarifications modeling electrical components ahead of 100% CDs to maintain fast-tracked projects. The Hatzel & Buehler VDC Team attends coordination meetings to help with the design-assist team with the vendors, manufacturers, engineers, and owners.

VDC/BIM TOOLS AND PROCESS

The Hatzel & Buehler BIM team has been using Revit for preconstruction since 2016. Understanding the phasing of a project, the VDC team can use the Revit model to identify prefab opportunities, allowing for more off-site production, and shortening the project schedule. Our Electrical Designers can then produce prefab submittals showing the design and construction teams what equipment will be shipped to site for install. This allows the procurement team a clear vision of what materials will need to be shipped to the prefab shop, and when. The BIM team can then make adjustments to the model based on deliver schedules and access.

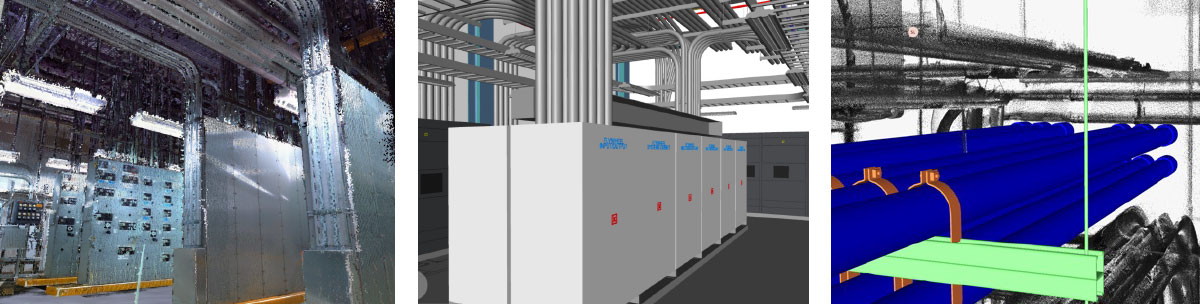

Hatzel & Buehler’s in-house electrical designer bring years of practical field experience, and knowledge to the preconstruction process. We can provide sealed drawings if needed but would prefer to work with the projects engineering team. The in-house engineering team utilizes programs such as ETAP, Polywater, AGI 32, Visual and other to preform underground feeder heat dispersion, pull tension, point loads, and photometric calculations. We have in house 3D scanning capabilities using Trimble X7 scanners, and Trimble total stations for point locations.

- Autodesk® Revit

- Autodesk® Navisworks

- Autodesk® Construction Cloud

- Manufacton Technologies

- eVolve Electrical

- Polywater

- PlanGrid

- Bluebeam Revu

- AutoCAD

- Trimble Total Station

- Trimble 3D Scanner

TRIMBLE X7 SCANNER

The Trimble x7 scanning process allows our team the following advantages:

- Scans of electrical manholes, duct banks and feeders.

- Reduction of workforce time and exposure to confined spaces

- Increased accuracy, 3D photos, and scalable point clouds that can be used in a BIM model

- Most accurate as-built.

X7 TRIMBLE SCANNER PROCESS

View The Slideshow Using The Controls